Subject: HPM PAPER CUTTING LINE HPM137GS22

-Paper Cutting Line Performance

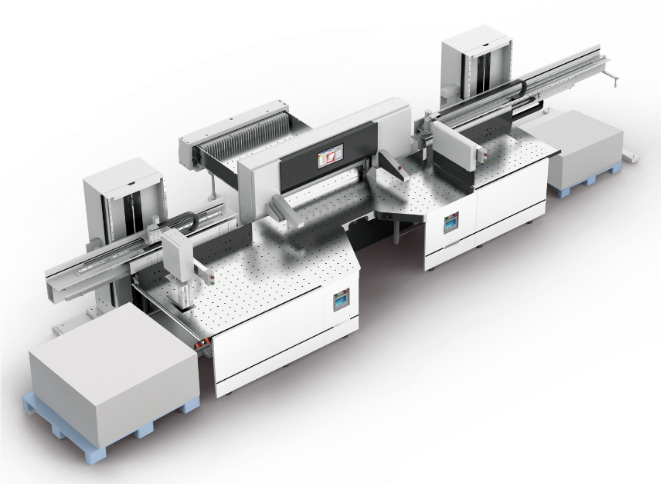

- Cutting line, consisting of paper loader, paper cutter, paper unloader, etc. Whole set of cutting line is designed to be efficient and reasonable , applying many patented technologies to achieve automatic paper loading, efficient paper cutting and automatic paper unloading, and paper loadingand unloading can be done simultaneously to max production efficiency and significantly reduce labour costs. With the latest industrial LCD touch screen, efficiency of cutting system reaches a whole new level.

- Cutting lineHPM-I-137, with a cutting height 210mm , giving it a significant advantage in terms of staff efficiency and high volume work.

- Cutting lines can perform perfectly in terms of efficiency, speed and streamlining of personnel. The front loading cutting line can automatically transfer the paper stack to platform, and the finished unloading stack can go directly to the downstream printing machine, saving the printing machine pre-loading staff.

Content

Loader QZ1450F

- Picture of Machine

- ConfigurationListing

- Machine Performance

- TechnicalParameter

- Latest highlights

Paper Cutter HPM137GS22

- Picture of Machine

- ConfigurationListing

- Machine Performance

- Latest highlights

- TechnicalParameter

- ComputerSystem S22

Unloader XZ1050S

1. Picture of Machine

- Configuration Listing

- Machine Performance

- Technical Parameter

- Latest highlights

Paper Cutting Line Floor Plan

Loader QZ1450F

-

Picture of Machine

2.Configuration Listing

| No. | Name | Brand, specification & model |

| 1 | Sensor | FOTEK |

| 2 | Air Switch | TE |

| 3 | AC Contactor | TE |

| 4 | Button | TE or Eton |

| 5 | Platform servo motors | Platform Walking(Inovance) |

| 6 | Servo Driver | Walking Control(Inovance) |

| 7 | Servo motor | Pick-up part(Inovance) |

| 8 | Photoelectric Sensor | Detecting the height of paper stacks(LEUZE) |

| 9 | Switch Power | TE |

| 10 | Power Switch | CANSEN |

| 11 | Miniature Relay | TE |

| 12 | Combination valves | Hydraulic Part(WAISN) |

| 13 | Air cylinder | Catch paper part(AirTAC) |

| 15 | Linear Guider | High accurate linear guides |

| 16 | Display screens | MCGS |

| 1 | Sensor | FOTEK |

| 2 | Air Switch | TE |

| 3 | AC Contactor | TE |

| 4 | Button | TE or Eton |

| 5 | Platform servo motors | Platform Walking(Inovance) |

3.Machine Performance

- Paper loaderhas many features such as high production efficiency, reduced labour intensity of the operator, short auxiliary production time and reduced labour costs.

- The automatic paper pick-up function automatically transfers the paper from the pile to the working platform, making the operation process safe and reliable.

- The machine is protected by a safety edge during operation. This ensures the safety of people around the machine during operation. The paper pick-up height can be adjusted at will. The hydraulic structure is used for lifting and lowering to ensure a smooth lift. The paper clamping function is pneumatically operated and the tightening force is adjustable for different paper types.

- Greatly facilitates the picking up of paper stacks during the cutting process. It provides the necessary prerequisites for future printing or folding processes, saving time and effort. The fully automatic paper pick-up function ensures simple operation.

4.Technical Parameter

| Model | Unit | QZ1450F |

| Loading Pattern | Pre-paper | |

| Plate Size

(W×L) |

cm | 130×128 |

| Max.loading size

(W×L) |

cm | 110×168 |

| Min.loading size

(W×L) |

cm | 45×56 |

| Max.loading height | cm | 16.5 |

| Max.Stacking height(with plate) | cm | 160 |

| Min. table height from the floor | cm | 15 |

| Max.loading weight | Kg | 350 |

| Pressure setting | MPa | 0.6 |

| Air Demand | MPa | 0.6 |

| Air supply consumption | L /min | 3 |

| Rated voltage | V | 380/220 |

| Power supply mode | Three-phase five-wire system | |

| Gross Power | Kw | 5 |

| Min.grams of paper | g | 50 |

| Loading Time | S | 25-40 |

| Net Weight | KG | 1850 |

| Gross Weight | KG | 1950 |

| Machine Size

(LXWXH) |

cm | 277.3×232.3×206 |

| Packing Size

(LXWXH) |

cm | 270×228×221 |

Note: The stacking angle should be adjusted for different paper types, which may result in slight variations in the maximum pick-up size.

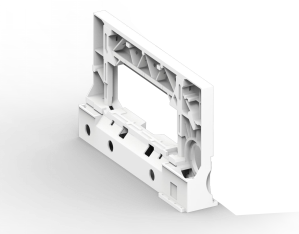

5.Latest highlights :

- The first national up and down movement using hydraulic structure, hydraulic system in the platform down without electricity, green energy saving, saving electricity costs, reliable work, smooth operation, no leakage phenomenon, can significantly reduce the cost of late maintenance.

- Adopt the patented overall frame type welded square steel structure base, the overall frame is solid, equipped with multiple adjustable bit chassis, easy to move and debug, can quickly adjust the level, and ensure the long-term work stability of the whole machine.

- The platform walking mechanism adopts servo motor with high-precision reducer, which is more responsive, with high accuracy of back and forth positioning, reliable and durable, and low maintenance cost, and the high-precision reducer is located above the cross beam, which is more reasonable in structure and safer in operation.

- Adopt the parameterized setting interface to ensure that all kinds of paper such as thick paper, thin paper and slippery paper can be taken smoothly.

- Adopting international brand photoelectric sensor to detect the paper pile fully automatically, the response is fast and reliable, and the action is fast and in place.

- When operating, the machine noise is the lowest in the industry, and the computer system is sensitive and reliable.

- Multi-servo control drive mechanism makes the whole machine run more smoothly and pick up paper more smoothly through the optimized parameter setting.

Paper Cutter HPM137GS22

1.Picture of Machine

2.Configuration Listing

|

No. |

Name | Brand, specification & model |

| 1 | Background LCD | 22’’Color touch Interface |

| 2 | PLC | HPM |

| 3 | Backgauge

position motor |

INOVANCE servo motor |

| 4 | Pick-up | FOTEK |

| 5 | Limit switch | TE |

| 6 | Guarding motor | TE |

| 7 | Air switch | TE |

| 8 | AC Contactor | TE |

| 9 | Miniature relay | IDEC |

| 10 | Switching power

supply |

TE |

| 11 | Power switch | CANSEN |

| 12 | Press-button | TE |

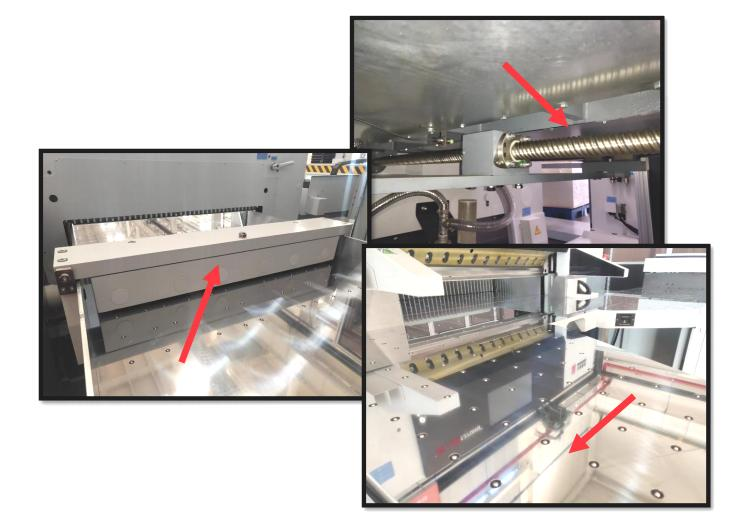

| 13 | Ball screw | High accurate (HIWIN) |

| 14 | Linear guider | High accurate double linear

Guides (JSM) |

| 15 | Hydraulic system | Combination Valve(VIS) |

| 16 | Oil Pump | BONDIOLI |

| 17 | Main Bearing | NSK |

| 18 | Work Table | Slotless and plated chromium

work table |

| 19 | Photocell | Sheng da |

| 20 | knife | HSS |

3.Machine Performance

1、Gantry casting structure is adopted to ensure high-precision of the structure in the assembly process, which improves the rigidity and stability of the cutter.

2、Worm gear system: large size worm gear, more cutting force, cutting more stable.

3、The knife bed adopts long slotted hole, which is convenient for quick knife change and adjustment.

4、Knife bed puller to ensure the safety of the machine, when the safety bolt is loose or broken, the machine will stop directly, without damaging the machine.

Smooth, precise and strong:

- The fully enclosed air cushion device makes paper movement very light and smoother.

- The paper pusher is linearly double guide rail guided and ball screw driven for smooth operation andprecise positioning.

- Integrated seamless working table with chrome-plated surface and good structural strength.

4.Latest Highlights

1.Equipped with imported proportional valve, easy to adjust the pressure on the computer screen without mechanical adjustment.

2.Large cutting capacity to meet the powerful cutting needs of print and packaging materials (210mm cutting height to increase production efficiency by 30%).

3.Adopting thickened knife bed with thickness of 110mm (more than the thickness of 90mm of ordinary knife bed), with thickened high-strength fuselage, better cutting rigidity, suitable for large-load cutting, and increasing 30% of the knife bed movable surface, with redesigned high-strength cutting tie rod, to meet the demand of high-load cutting force;

4.Large-size high-strength worm gear ensures stable work under high load and longer life;

Large-size flywheel and brake pads ensure the stability of the machine when cutting under heavy load.

5.The net weight of the whole machine is increased from 4100kg to 5300kg, which improves the rigidity of cutting and solves the problem of insufficient rigidity of ordinary paper cutter, resulting in better cutting quality.

5.Technical Parameter

| Model | Unit | 137G |

| Max.Cutting Width | cm | 137 |

| inch | 53.9 | |

| Max.Cutting Length | cm | 145 |

| inch | 57.1 | |

| Max. Cutting Height | cm | 21 |

| inch | 8.3 | |

| Min. Cutting Size

(without false clam plate) |

cm | 3 |

| inch | 1.2 | |

| Min. Cutting Size

(with false clamp plate) |

cm | 9 |

| inch | 3.5 | |

| Front Table Length | cm | 73 |

| inch | 28.7 | |

| Max.Clamp Pressure | N | 52000 |

| Max. Cutting Speed | time/min | 46 |

| Main Motor | KW | 5.5 |

| Net Weight | Kg | 5300 |

| Gross Weight | Kg | 5800 |

| Packing Size(L×W×H) | cm | 330×205×233 |

7.ComputerSystem S22

- 22inch full touch display screen, with program setting.

- Can parse PDF, JDF format files, and can parse various irregular spelling files.

- Automatically generate cutting size and pictures of cut products. Computer automatically guides workers to cut. Reduce the requirement for personnel and avoid errors.

- Computer with wired network, wireless WIFI connection function, leaving a U disk interface can be directly from the computer to read or copy files, analysis.

- Support scanning two-dimensional code, easy to find the generation of files to be cut, direct access to the program, to avoid the tedious steps of manual search.

- Backgauge speed up to 38m/min.

- German operating system is equipped to meet the operating habits of domestic users and guarantee convenient operation;

- Mainboard adopted industrial chip imported from Italy;

- Highly sensitive of the touch screen has real-timeresponses;

- Equipped with signal amplification function and excellent anti-interference to avoid dimension errors due to driveaging;

- Dimension in front of knife will be displayed to facilitate sizes forcutting;

- Program storage capacity is 300 programs,each program can store 200 items cutting

- computing with four operations, output programs in realtime;

- Equipment has relative positioning function relative to current position;

- With minimal compensation, it can rapidly correct program errors due to paper distortions;

- It can rapidly find out user-defined number ofcutters;

- Each air cushion program can beprogrammed;

- The time of automatic cutting signals can be set up and cancelled; single automatic cutting can be started by inputting apassword;

- High and low speeds can be manually switched overrapidly;

- A paper-pushing program is equipped to push paper automatically so as to guarantee safety and enhance operationefficiency;

- Automatic cutting can be made as per instructedprogramming;

- Display precision is01mm;

- Multiple languages such as Chinese and English are available for order management;

- Manual and automatic operations can be rapidly switched over to enhance efficiency to the greatestextent;

- Voice messages are equipped to make users judge equipment conditions correctly.

Unloader XZ1050S

1.Picture of Machine

2.Configuration Listing

No. Name Brand, specification & model 1 Sensor FOTEK 2 Air Switch TE 3 AC Contactor TE 4 Button TE or Eton 5 Platform servo motors Platform Walking(Inovance) 6 Servo Driver Walking Control(Inovance) 7 Servo motor Pick-up part(Inovance) 8 Photoelectric Sensor Detecting the height of paper stacks(LEUZE) 9 Switch Power TE 10 Power Switch CANSEN 11 Miniature Relay TE 12 Combination valves Hydraulic Part(WAISN) 13 Air cylinder Catch paper part(AirTAC) 15 Linear Guider High accurate linear guides 16 Display screens MCGS 3.Machine Performance

- The paper unloader can be used in conjunction with program-controlled paper cutters, lifters, paper breakers and air cushion workstations to form a cutting line, which can automatically complete the cutting, feeding and unloading, sorting, handling and stacking of paper, with many features such as high production efficiency, low operating labour intensity, short auxiliary production time and reduced labour costs.

- It greatly facilitates the feeding and unloading of paper stacks during the cutting process. The high quality stacking function provides the necessary prerequisites for future printing or folding processes, saving time and effort. The fully automatic paper size adjustment function guarantees simple operation.

-

TechnicalParameter

Model Unit XZ1050S Plate Size (W×L)

cm 94×134 Max.Paper size (W×L)

cm 90×130 Min.Paper size (W×L)

cm 30×40 Max.Layer height(with plate) cm 160 Max.Layer height cm 16.5 Min. table height from the floor cm 15 Max.Layer weight Kg 350 Pressure setting MPa 0.35-0.4 Air Demand MPa 0.6 Air supply consumption L /min 3 Rated voltage V 380/220 Power supply mode Three-phase five-wire system Gross Power Kw 4.3 Min.grams of paper g 50 Unloader time S 20-35 Net Weight KG 1650 Gross Weight KG 1750 Machine Size (LXWXH)

cm 307.6×178.2×206 Packing Size (LXWXH)

cm 318×206×221 -

Latest Highlights

- The first national up and down movement using hydraulic structure, hydraulic system in the platform down without electricity, green energy saving, saving electricity costs, reliable work, smooth operation, no leakage phenomenon, can significantly reduce the cost of late maintenance.

- Adopt the patented overall frame type welded square steel structure base, the overall frame is solid, equipped with multiple adjustable bit chassis, easy to move and debug, can quickly adjust the level, and ensure the long-term work stability of the whole machine.

- The platform walking mechanism adopts servo motor with high-precision reducer, with rapid response, high positioning accuracy, reliable and durable, low maintenance cost, high-precision reducer is located above the beam, with more reasonable structure and safer operation.

- Adopt the parameterized setting interface to ensure that all kinds of paper such as thick paper, thin paper and slippery paper can be unloaded smoothly.

- Adopting international brand photoelectric sensor to detect the paper pile fully automatically, the response is fast and reliable, and the action is fast and in place.

When operating, the machine noise is the lowest in the industry and the computer system is sensitive and reliable.

- Multi-servo control drive mechanism makes the whole machine run more smoothly and unload paper more smoothly through optimized parameter setting.

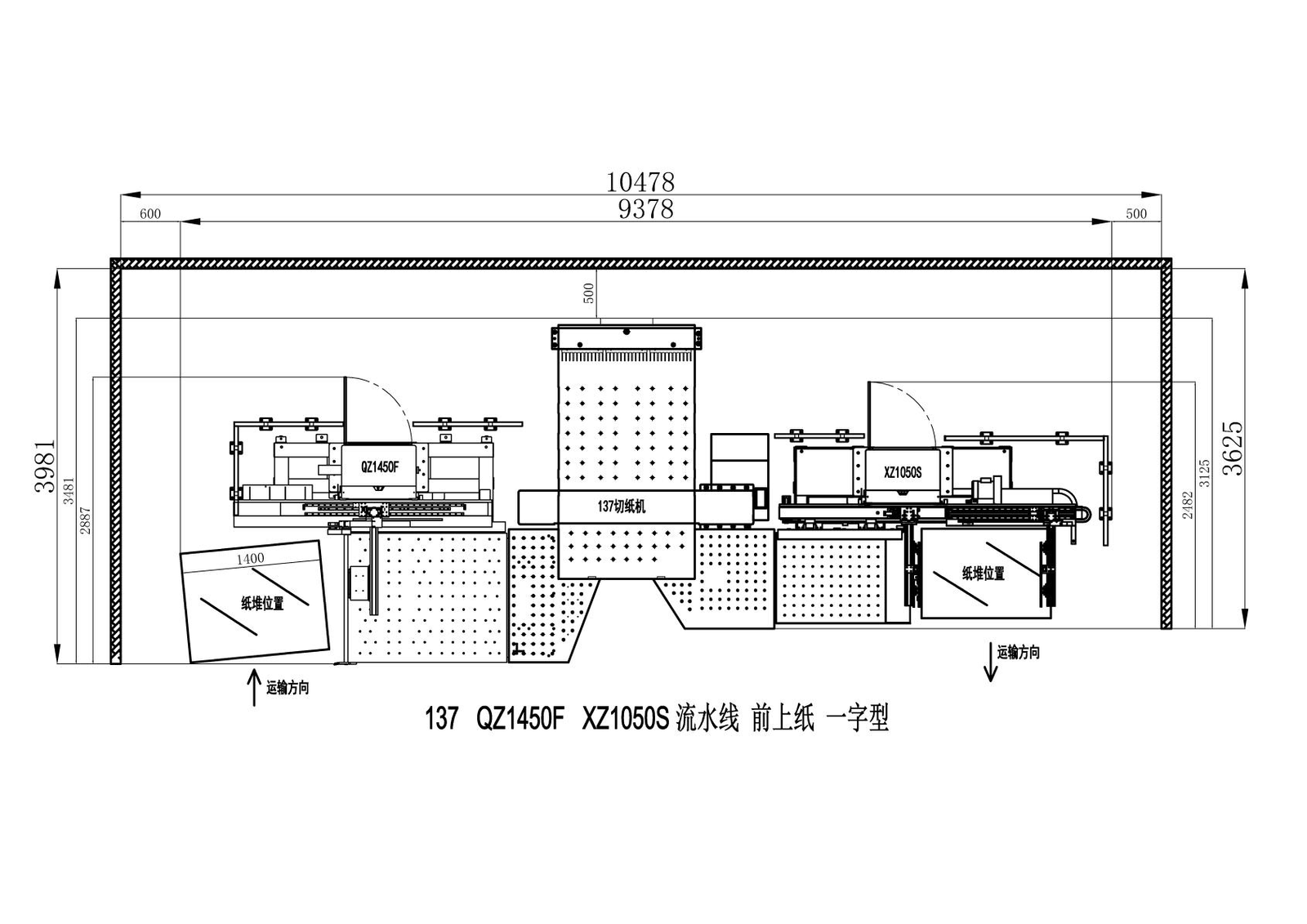

Paper Cutting Line Floor Plan

PAPER CUTTING MACHINE FLOOR PLAN

PAPER CUTTING MACHINE FLOOR PLAN